Packaging bags are not only a daily necessity but also a display of corporate image. Through professional design and exquisite craftsmanship, we can make unique packaging bags to meet the needs of customers with different requirements. This article informs you of the process flow of gravure printing customized packaging bags in great detail.

What is Gravure Printing?

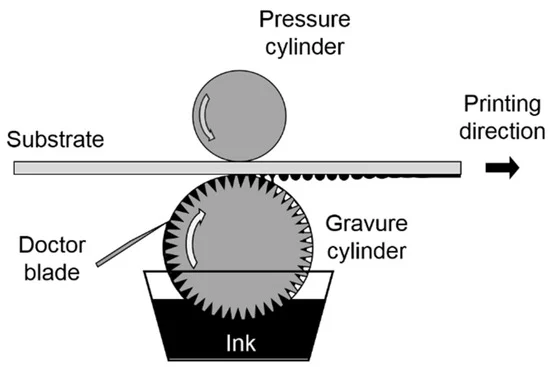

Gravure Printing is an intaglio, high-resolution printing process that produces intricate and complex images on various substrates ranging from paper and film to flexible packaging. It is commonly applied for mass production of products such as magazines, packaging, wallpaper, and labels.

How It Works?

In gravure printing, the image or text to be printed is engraved on the cylinder of the gravure printer surface with small depressions (cells) that recess ink. The engraved cylinder is painted with gravure printing ink. Then cylinder surface is wiped clean, and ink remains in the recessed cells. Finally, when the cylinder rotates, the ink of the cells is transferred to the substrate (i.e., paper or plastic film) by direct contact, often with the help of a blanket cylinder.

Process Flow of Customized Gravure Printing Packaging

Personalized gravure printing packaging, as a sophisticated printing technology, has been widely used in food soft packaging and daily necessities soft packaging due to its unique visual effect and persistence. To meet customers and ensure the aesthetics and utilization function of packaging, the operation sequence of gravure printing is rather crucial.

Confirm the Order

The first thing in the process is order confirmation and customer communication. Salespersons need to learn clearly about customers’ needs, including packaging type, size, printing content, material requirements, and delivery time. Through accurate communication, enable the orderly completion of the subsequent design and print work.

Confirm the Design

Design is the determining factor in gravure printing, which directly affects the printing result and the aesthetics of the end product. Our designers need to talk with customers in detail about the product image and brand idea to ensure the design will be in line with the brand tone. The design department will make patterns, colorways, and layouts that meet the demand based on the information that customers provide. At the same time, the feasibility of the print process must also be considered to ensure that the design can be accomplished on the gravure print machine.

Placemaking

Platemaking is the most important link of gravure printing and has a direct influence on the quality and accuracy of the printed pattern. Designers need to communicate in detail with the platemaking plant and accurately create gravure plates according to the design drawings. The following points need to be observed when making plates:

- Pattern Precision: Ensure the texts and patterns in the design are subtle and clear so as not to create blurry print effects due to low precision.

- Color Matching: Depending on the range of colors of the printed material, choose the matching color of gravure printing ink to ensure the printed pattern is in tandem with the original material color.

- Layout Adjustment: According to the printing demand of the gravure printer, adjust the layout in such a way that there would be no color cast or shift printing during printing.

Printing

The printing ink is a key link in gravure printing and determines the visual effect of the finished product. During printing, the workshop technicians have to monitor the printing quality to ensure the gravure printing ink is evenly applied to avoid color discrepancy, and the printing speed is moderate to avoid distorting the pattern due to high speed. At the same time, pay attention to whether the edges after printing are smooth and if there are spots or bubbles.

Composite

Flexible packaging materials (kraft paper, composite materials, etc.) are printed using composite technology. The workshop technicians must make sure that the printed pattern can be correctly set on the packaging material. In the process of composite, the material’s adhesive and pressure must be controlled to maintain the pattern firmly and not detach. In addition, the composite material needs to be dried out to eliminate residue moisture after printing.

Curing

Curing is a very important process of gravure printing. We need to put the composite packaging film in the curing room to cure it so that it does not peel off or shift during long-term usage. After curing, the packaging material needs to be checked to observe if the pattern is distinct and solid.

Slitting

Slitting is the cutting of printed composite material into normal packaging bags. The workshop staff needs to form a slitting team to cut packaging bags of different specifications according to the order specifications. In slitting, one should be careful to ensure that the cutting is precise so as not to have incomplete patterns or irregular packaging due to slitting errors

Bag Making

Bag making is to place the slit materials into the end product shape. The employees should ensure the bag’s mouth is well closed so that the content will not leak. At the same time, the sealing of the bag mouth should also be paid attention to, whether punching holes, mounting air valves, etc. are required to meet customer needs.

Quality Inspection

A strict quality check is required at every link after production is completed. The products at every link should be inspected by the quality inspectors to ensure that the printed pattern is not obscured, the color is uniform, and the material is not torn. While checking the quality, if anything goes wrong, it should be corrected at once and informed to the production team to ensure that the problems are corrected timely.

A Sophisticated Technology

There are a few links from order confirmation to quality inspection in the gravure printing packaging procedure, and each of them should be carried out carefully. With professional design, precise plate making, good-quality printing, and stable lamination technology, gravure printing can provide customers with high-quality and high-aesthetic products. Salesmen should understand the importance of each link in detail and communicate well with customers to ensure that the final product can meet customer requirements.

Huiyang: Elevating Brands with Premium Custom Flexible Packaging Solutions

-1.webp)

Huiyang Packaging is a leading company in customized flexible packaging solutions, such as food packaging bags, daily chemical packaging, and packaging films. We are an expert in serving brands of all sizes to cultivate and expand by providing the best flexible packaging for food and non-food applications.

As one of the leading gravure printing companies in the business, Huiyang uses state-of-the-art gravure printing technology to create colorful, accurate, and long-lasting designs. This latest print technology guarantees high-quality color reproduction and top-notch print quality, making us a reliable partner for companies wanting to raise their packaging game. From improving shelf attractiveness to protecting product integrity, Huiyang’s gravure printing performance is beyond compare and dispute.