Tilpassede fleksible emballagetjenester

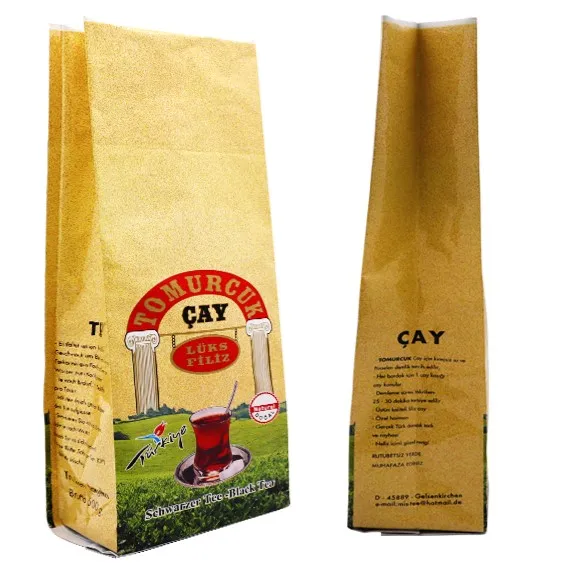

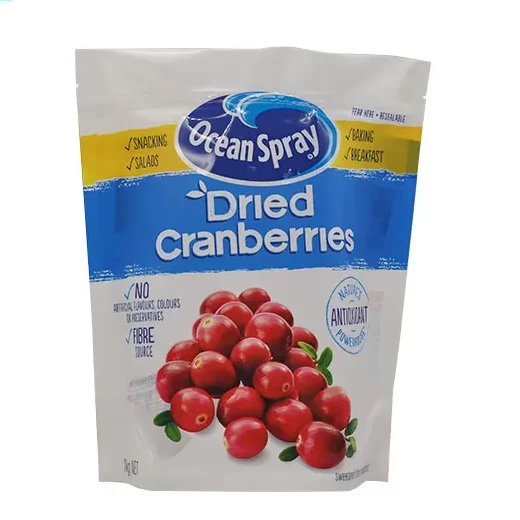

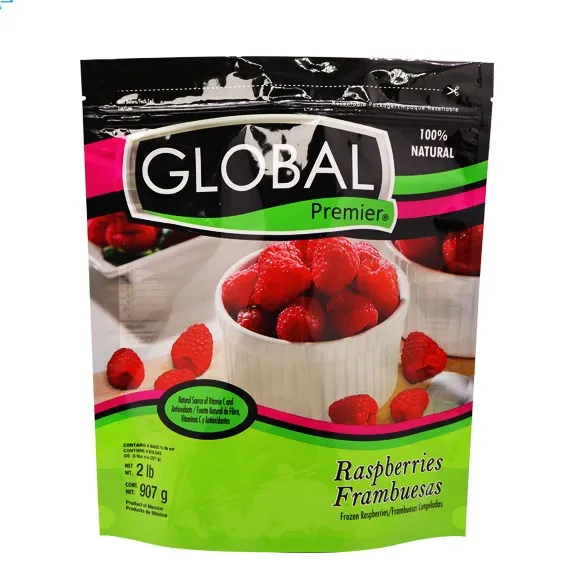

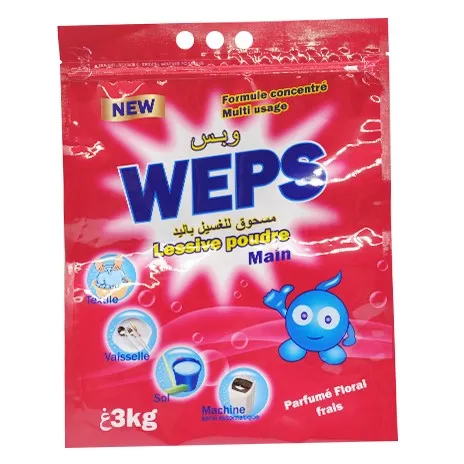

Huiyang Packaging tilbyder et komplet udvalg af tilpassede fleksible emballager og folietilpasningstjenester, der tilpasser tykkelse, materiale, størrelse, tryk og andre egenskaber i henhold til kundernes behov. Uanset om det er poser til fødevareemballage, Emballageposer til daglig kemi, filmemballage, eller andre industriers emballagebehov, kan vi levere de bedste løsninger til vores kunder.

Vores tilpasningstjenester er designet til at give vores kunder kvalitet, innovative og personaliserede emballageprodukter der hjælper dem med at skille sig ud på markedet.

Brugerdefineret fleksibel emballagefilm Produktkasse

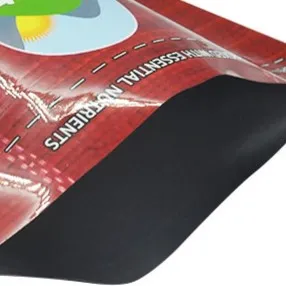

Vi har skabt personlige fleksible emballagefilm, der er designet til at fremhæve vores kunders brandimage og produktegenskaber. Disse tilpassede fleksible emballager har unikke designs og farver, der giver kunderne karakteristiske emballageløsninger.

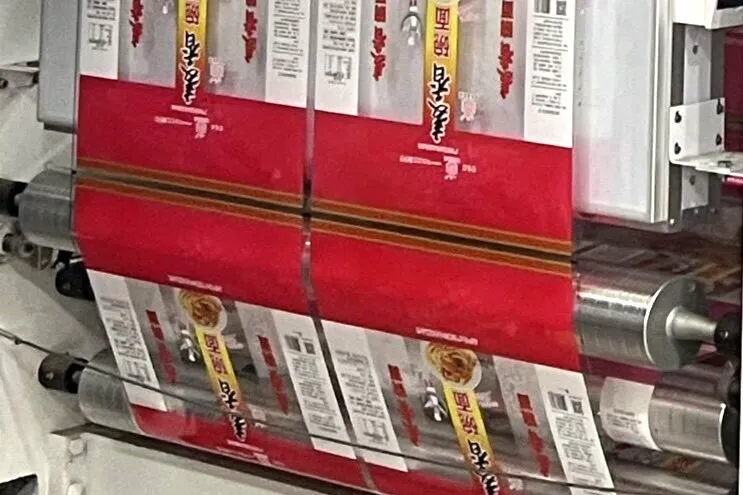

Avanceret printudstyr og moden printteknologi

Ved hjælp af avanceret printudstyr og processer, der giver højere printnøjagtighed og printhastighed, kan vi opnå op til 10 farver af tryk, hvilket giver produkter med et væld af farvevalg og overfladebehandlingseffekter for at imødekomme behovene hos forskellige produkter og mærker af personlige tilpasset fleksibel emballage.

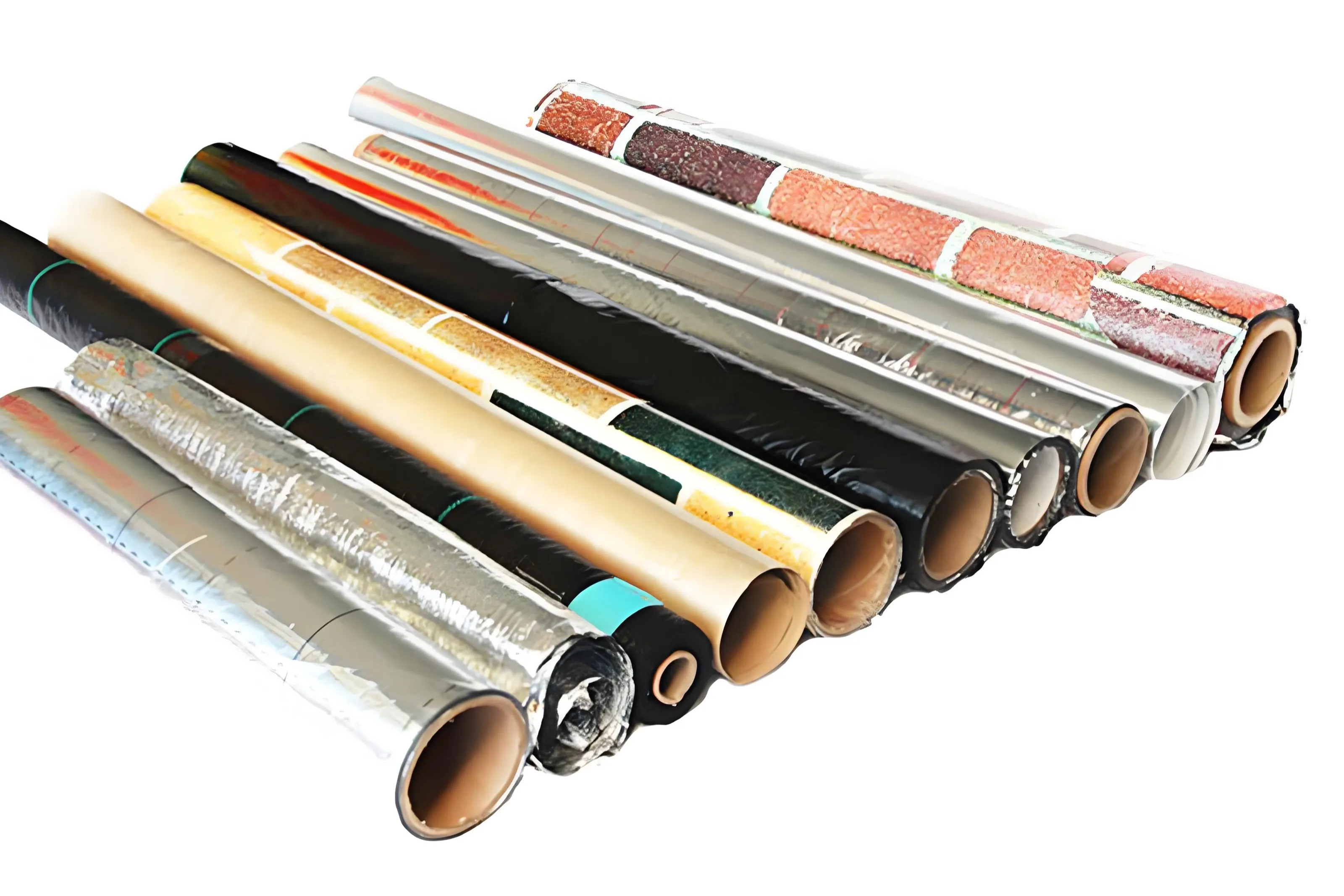

Analyse af råmaterialerne til brugerdefinerede fleksible emballagefilm

De almindelige råmaterialer til fleksibel emballagefilm omfatter PE-film, PET-film, BOPP-film, VMPET-film (aluminiseret polyesterfilm), AL-film (aluminium-platin), VMCPP-film, CPP-film og andre materialer. Med god fleksibilitet, gennemsigtighed og holdbarhed bruges det i vid udstrækning til fødevarer, daglige kemiske forsyninger, medicinske forsyninger og andre emballageområder. Der er også miljøvenlige materialer at vælge imellem, f.eks. biologisk nedbrydelig plast og genanvendelig plast. Disse miljøvenlige materialer har bestået certificeringscertifikater, såsom EN13432, ASTM D6400 osv., og er blevet bredt anerkendt med hensyn til bæredygtig udvikling og miljøbeskyttelse.

Skræddersyet fleksibel emballagesortering til alle brancher

Vores tilpassede fleksible emballageløsninger henvender sig til alle brancher og leverer skræddersyede posesorteringstjenester, der opfylder forskellige behov.

Stå op-pose

Lynlås-pose

K-Seal Stand Up Pouch

Quad Seal-pose

Pose med tud

3 siders forsegling

3 siders forseglingspose

Formet pose

Fin/Lap Seal-pose-Front

Fin/Lap-forsegling med sidekile foran

Lågfilm

Krympemuffe/Labl

Rullelager

Fin/Lap Seal-pose-ryg

Fin/Lap-forsegling med sidekile på bagsiden af posen

Sådan vælger du den rigtige fleksible emballagepose til dine behov

Huiyang Pakkumulering tilbyder en række specialfremstillede fleksibel emballagefunktioner som lynlåse, ophængningshuller, afrivninger og tude samt en række muligheder for overfladebehandling og specialiserede materialevalg for at imødekomme forskellige produkters behov og forbedre emballagens anvendelighed og brandets image.

Lynlås

Lynlåsdesignet er nemt at åbne og gør det nemmere at forsegle og genforsegle pakken.

Hæng hullet op

Design med hængende huller til praktisk udstilling og forbedring af produktbilledet.

Tear Hotch

Tear hotch-design til hurtig åbning og nem adgang til produktet.

Tud

Professionelt tuddesign til flydende og granulære produkter, der sikrer brugervenlighed og ingen lækage.

Gennemsigtigt vindue

Gennemsigtigt vinduesdesign giver forbrugerne mulighed for at visualisere produktegenskaber og øge tilliden til købsbeslutninger.

Tilpasset form

Tilpassede former for at skabe et unikt emballagebillede i henhold til produktegenskaber og markedets efterspørgsel.

Høj dampbarriere

Det højeffektive fugtbarrieredesign beskytter produkterne mod fugt og forlænger holdbarheden.

Muligheder for overfladebehandling

En række muligheder for overfladebehandling, herunder mat, soft touch og blank. Giver et skræddersyet emballageudseende.

Film

Specialiserede materialevalg, herunder høj barriere, høj temperatur, punkterings- og rivestyrke.

Forskellige størrelser

Der findes forskellige størrelser til at opfylde forskellige produktspecifikationer og emballagebehov, hvilket øger emballagens anvendelighed og fleksibilitet.

Valgmuligheder for posebund/kile

Pouch Bottom-, Four Seal- eller Three Side Seal-designs til forskellige produktformater.

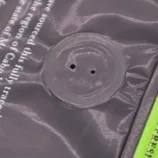

Åndedrætshul

Designet med åndingshuller sikrer luftcirkulation inde i pakken for at bevare produktets friskhed.

Trin til at personliggøre din tilpassede fleksible emballageløsning

Efterspørgselsanalyse og kommunikation

Først og fremmest skal vi kommunikere fuldt ud med dig for at forstå produktets egenskaber, brand image, markedspositionering og specifikke behov for emballage. Dette omfatter forståelse af emballagens funktionelle krav, designstil, materialevalg osv.

Design og forslag

Design en eksklusiv emballageløsning i henhold til dine behov og krav. Det kan indebære diskussioner om emballagedesign, materialevalg, trykeffekter osv. Designteamet vil normalt give kunden flere muligheder at vælge imellem og ændre og justere dem baseret på din feedback, indtil de opnår tilfredsstillende resultater.

Forberedelse og validering af prøver

Når designet er fastlagt, produceres en prøve til din bekræftelse. Prøverne kan bruges til at vurdere, om pakkens udseende, tekstur, funktion og andre aspekter opfylder behovene. Hvis det er nødvendigt, kan der udføres flere prøvebekræftelser, indtil den endelige tilfredshed er opnået.

Masseproduktion og levering

Efter bekræftelse af prøven begynder masseproduktionen. Produktionsteamet vælger den rigtige produktionsproces og udstyr i henhold til dine ordrekrav for at sikre rettidig levering af tilpassede emballageprodukter af høj kvalitet.

Har du stadig spørgsmål? Fortæl os om dine bekymringer, og lad et team af professionelle hjælpe dig!

Optimerede skræddersyede fleksible emballager

1. Foreløbig kommunikation af efterspørgsel og undersøgelse af kvalitetskontrol

Vi mødte en amerikansk kunde på Canton Fair, som kom til os med en kyllingepose til forespørgsel. Under den første kontakt fik vi mere at vide om kvalitetsproblemerne med poser produceret af deres tidligere leverandør, og kunden var nødt til at finde en ny leverandør. Gennem kommunikation med vores kunder får vi en detaljeret forståelse af deres emballagebehov, herunder materialestruktur, tykkelse, posetype og -størrelse. Samtidig tager vi posen med tilbage til kvalitetskontrolafdelingen for at teste materiale og tykkelse for at sikre, at vi kan give kunden et præcist tilbud.

2. Forbedring af design og holdbarhedstest

Baseret på resultaterne af den indledende kommunikation om krav satte vores designteam sig for at redesigne taskens håndtag og give kunden en række forskellige designmuligheder at vælge imellem. Efter kundens bekræftelse overførte vi designet til produktion og udførte flere holdbarhedstests. Resultaterne var dog ikke ideelle, og vi er klar over, at der er behov for yderligere forbedringer.

3. Funktionsoptimering og materialeopgradering

Vores forsknings- og udviklingsteam trådte til igen for at optimere taskens håndtag yderligere. Efter gentagen kommunikation og testning med kunden besluttede vi at justere materialestrukturen i posens indre og ydre lag for at forbedre brugsoplevelsen. Samtidig har vi i henhold til kundernes krav udskiftet genanvendelige miljøbeskyttelsesmaterialer for at forbedre produkternes miljømæssige ydeevne.

4. Endelig levering og kundetilfredshed

Efter mange forbedringer og tests lykkedes det os endelig at levere emballageløsninger af høj kvalitet, der opfylder vores kunders behov. Vi leverede det endelige produkt til vores kunder og modtog deres store anerkendelse og tilfredshed. Mens vi sikrer produktkvalitet og leveringstid, tager vi altid kundernes behov som vores retning og drivkraft og forfølger konstant produktinnovation og optimering.

Kontakt os

Del dine behov, og kom i kontakt med vores erfarne producent af fleksibel emballage. Udfyld formularen for at få tilpassede fleksible emballageløsninger, der forbedrer dit brand. Kontakt Huiyang Packaging i dag!