A packaging bag is more than just a soft container. With time, it has evolved into a tool with added publicity. At the same time, it also bears the responsibility of maintaining the integrity of food safety. In this article, Huiyang Verpackung will analyze different types of packaging bags, material selection, and the green practices behind them.

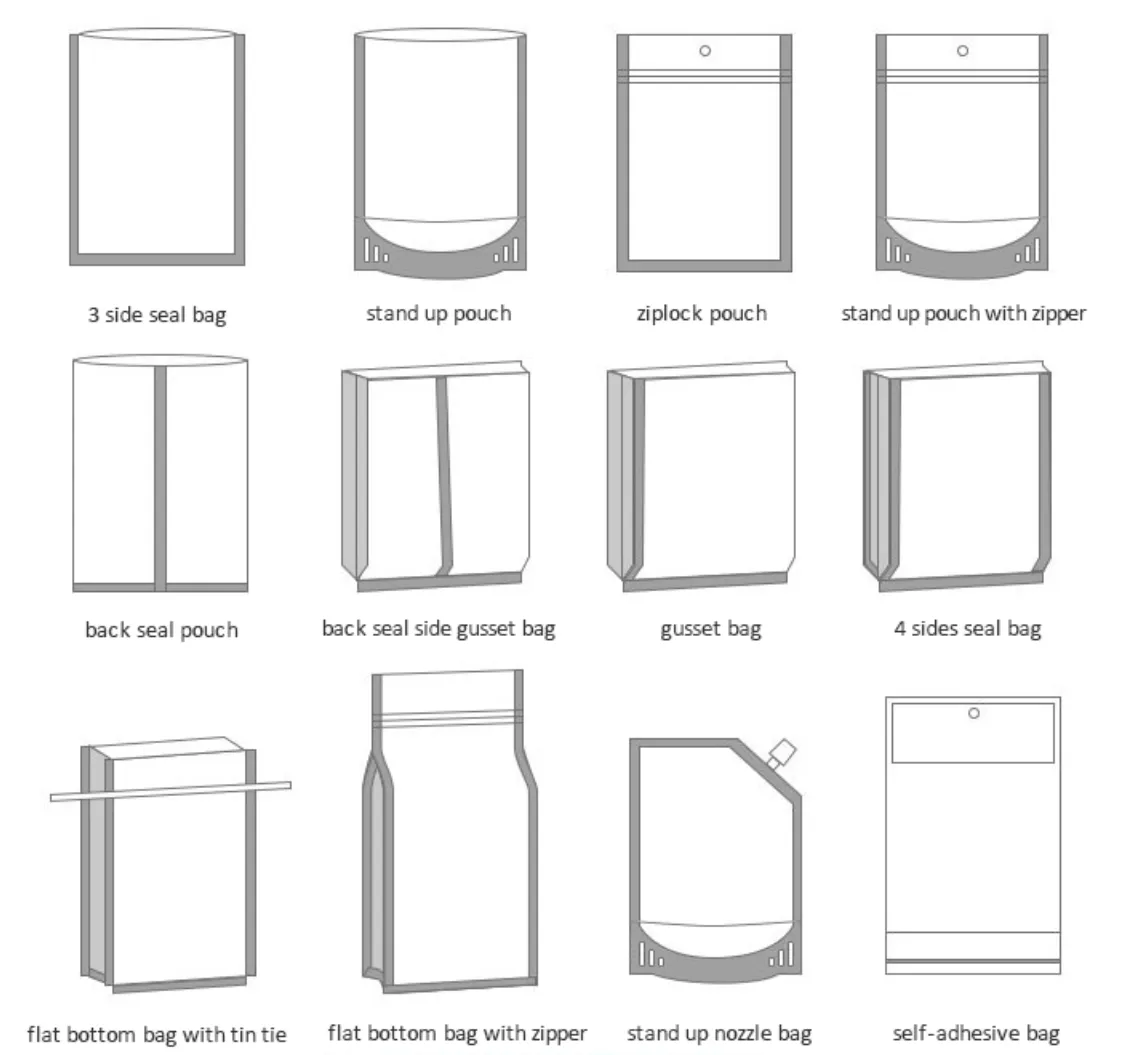

Types of Packaging Bags

Stand Up Pouch

Stand-up pouches have always been popular in the market for their practicality and visual appeal. The addition of a zipper at the closure of the bag allows it to be resealed after opening, adding to the bag’s utility. It is suitable for a wide range of food products such as snacks, cereals, coffee, milk powder, etc. Its vertical layout ensures optimal visibility in supermarket retail displays.

Flat Pouch

The first choice for disposable or promotional items. Since flat bags are more space-efficient than vertical bags, they are generally used to package condiments, sauces, or ready-to-eat mixes.

Spout Pouch

A reusable plastic spout on the top or slant of the bag. This design is more cost effective in packaging than rigid packaging and the package itself is relatively lightweight.

Of course, there are many more bag types on the market and we have only listed a small selection of them, so head over to view more details. If we do not follow the structure or form, we can also classify bags with specific functions, which are categorized based on their particular use and function.

Functional Packaging Bags

Retort Pouches

A steaming bag is a bag that can be steamed and can withstand high temperatures. It allows the bag to be heat-treated and withstand temperatures of up to 121°C. It is the first bag to be developed for food packaging. It is a breakthrough in the development of food packaging bags. The steaming bag extends the shelf life of food without refrigeration. It not only saves costs but also facilitates transportation and storage of cooked food. It is commonly used for cooked foods, meats with soups and sauces.

Vacuum Pouches

A vacuum bag means that the air in the bag can be removed before the bag is sealed, extending the shelf life of the food and facilitating its storage and transportation. It is ideal for packaging meat, seafood, and selected dairy products.

Classification of Packaging Bag Materials

- Plastic: Plastic is the most commonly used packaging material due to its low cost and versatility. However, due to sustainability concerns, several countries have implemented plastic bans, which is driving changes in material upgrades and options.

- Aluminum: Aluminum has strong barrier properties that prevent moisture, and oxidation, and extend the shelf life of food. However, due to its complex recycling process, aluminum will be subject to greater environmental scrutiny.

- Biodegradable Materials: Plastic packaging cannot meet the requirements of eco-environmental protection. People have upgraded the raw materials of the original plastic packaging and developed a new generation of green packaging and biodegradable plastic packaging. Of course, its price will be higher than ordinary plastic.

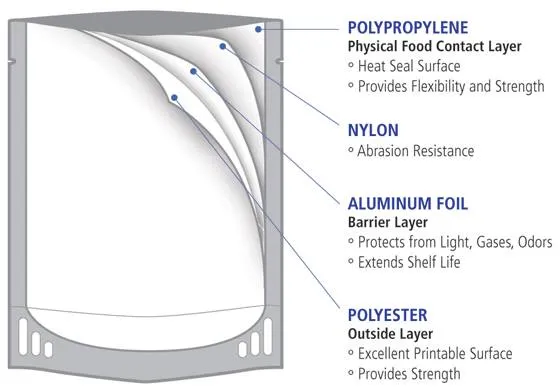

- Composite Plastic Packaging: Laminated materials usually combine the best performance of different materials, and the combined structure of materials, such as plastic and aluminum, can be used according to the characteristics of different products to create more practical but distinctive pouches. As we all know, as a carrier for carrying content and brand promotion, the amount of information it carries is also one of the decisive factors in deciding whether a customer buys or not.

Sustainable Flexible Packaging Practices

As people become more environmentally aware of the dangers of non-biodegradable plastics to the environment, biodegradable bags are gradually replacing ordinary plastic bags. Biodegradable packaging is usually made from corn starch or other plant sources. It is both safe and environmentally friendly but is expensive. More recyclable packaging has also emerged from consumer concerns and the oversight of eco-friendly organizations.

Reusable alternatives Reusable bags made from stronger materials are penetrating the market, targeting environmentally conscious consumers who are willing to invest in sustainable packaging solutions.

- Convenience: Contemporary consumers prioritize ease of use, making reusable packaging such as zipper bags and nozzle bags popular.

- Environmental Awareness: With slogans such as green ecology and environmental protection gaining popularity, people are also considering the safety and environmental friendliness of bags when purchasing products.

As society progresses and people’s consciousness changes, the style elements and materials of packaging bags are also changing to meet the sustainable concept of consumers, it is no longer just a simple container, it is an advertisement and a driving force for people to consume, and consumer expectations are the driving force for reform and innovation in this industry.

The Future of Packaging Bags

The future of packaging bags will tend to be more recyclable and biodegradable materials to meet environmental requirements. Basic attributes such as zippers, valves, personalized design, and printing will continue to be upgraded to meet the needs of the times.

Packaging bags are no longer simple food containers, which carry brand communication and environmental responsibility. As consumers’ demands for environmental protection and practicality increase, the packaging industry will continue to innovate to meet new market demands.