With the diversified choices of food, the requirements for safety, convenience, and sustainability of foods by consumers have risen. Packaging continues to play a paramount role in keeping foods safe, fresh, and easily transmittable. From so many packaging options, one which has gained immense popularity is the retort pouch due to its superior performance in the preservation of foods under high temperatures. But what is a retort pouch and how does it work?

What is a Retort Pouch?

The pouch type of flexible packaging is called a retort pouch, which withstands high pressure and high-temperature conditions for the sterilization of its contents. This kind of packaging is extremely important in the food industry because safety and long shelf life are concerns. Retort pouch definition: A specially designed heat-resistant multi-layer pouch that finds its application for ready-to-eat meals, sauces, and many more food items requiring sterilization.

Retort Pouch Material and Structure

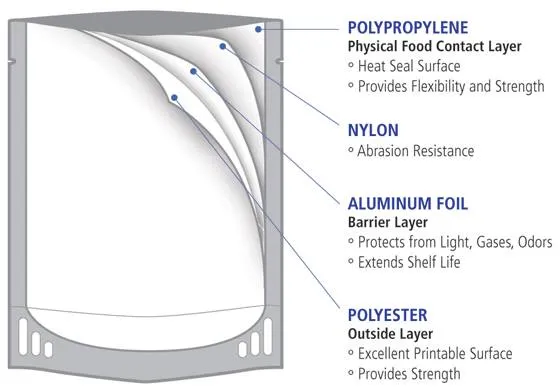

The material structure of a retort pouch is designed for maximum protection against external factors such as moisture, oxygen, and light, which could compromise the quality of food. The material of the typical retort pouch would consist of a multitude of layers, each serving a specific function.

- Outer layer: As the outer layer of the retort bag, it needs to have excellent wear resistance and puncture resistance, to effectively protect the inner layer from damage; secondly, it needs to be well compounded with the inner layer, so it needs to have good thermal stability and mechanical strength. Therefore, we generally choose PP and PE as the outer layer of the retort bag.

- Intermediate barrier layer: To achieve better barrier properties, a layer of barrier material is usually compounded under the outer layer, such as AI and EVOH. AL has strong moisture-proof, anti-oxidation, and light-shielding effects, and EVOH has good gas barrier properties. The combination of the two can provide double protection for food.

- Heat seal layer: This layer is the material that comes into direct contact with food, so it must be non-toxic and harmless and meet food safety standards.

Generally, we choose PP and PE. This type of material is easy to bond with other layers to form a complete packaging system, and they can melt and seal within a specific stable range to ensure the tightness of the packaging.

Retort Pouch Packaging: Some Advantages

Extended Shelf Life

Retort bags generally use high-temperature resistant multi-layer composite high-barrier films, with a maximum heat resistance of up to 135°C. After high-temperature sterilization to eliminate bacteria at the source and then sealed, the contents of the retort bag can effectively isolate oxygen, moisture, and other harmful substances, ensuring that the products inside the package are protected from external influences, thereby extending the shelf life and avoiding food waste.

Convenience and Space Efficiency

Compared to traditional cans or bottles, flexible retort pouch packaging is much lighter and less bulky. As a result, the product is easier to store and transport; this is very important for both manufacturers and consumers. In addition, flexible retort pouches are easier to handle; they are therefore very suitable for on-the-go consumption.

Sustainability

With the ever-growing demand for sustainable solutions, recyclable retort pouches have cropped up. These pouches are made either from materials that are recyclable or biodegradable, hence giving a greener alternative to conventional packaging. This trend is of special importance as manufacturers and consumers alike become more conscious of reducing plastic waste.

Improve User Experience

The outer packaging of the retort bag can be designed to cater to the marketing needs of consumers and manufacturers. To improve the consumer experience, the retort bag can be equipped with zippers, easy-tear edges, or other convenient devices to enhance the practicality and convenience of the product.

Application Areas of Retort Pouch

- Meat products: Oxidation and bacterial growth will cause ready-to-eat meat to deteriorate in the air and become inedible, so we use retort bags to package meat. Through high-temperature sterilization and vacuum packaging, bacteria are eliminated at the source. After strict sealing, the meat maintains its freshness and flavor while retaining the nutrients of the meat to the maximum extent. Bag packaging is convenient for carrying outside and meets people’s leisurely lives.

- Seafood: The retort bag uses ultra-high temperature sterilization to kill bacteria at the source while quickly locking in the moisture of the seafood itself, preventing the product from losing weight due to dehydration and retaining the original flavor of the seafood. After being sealed, it can avoid odor and contamination.

- Fruit and vegetable beverages: Fruit and vegetable beverages rich in vitamin C and other antioxidants, are generally filled in retort bags and commercially aseptically operated. This can not only well preserve the active factors in the juice and extend the shelf life, but also meet people’s demand for ready-to-drink beverages.

- Other uses: Retort bags are also widely used in many fields such as pet supplies, emergency food, medical supplies, military supplies, etc. The wide application of retort bags can greatly reduce the use of preservatives and add points to people’s dietary health.

What Does the Future Hold for Retort Pouches?

Retort pouch means not only a packaging solution but an advanced, versatile, eco-friendly option for a broadened circle of applications. With innovations in flexible retort pouches and a growing focus on environmental sustainability, the outlook for retort pouch packaging appears very bright.

Huiyang Ambalaj, as a retort pouch manufacturer, will continue to develop more efficient and environmentally friendly packaging solutions and change the face of food packaging. We also provide OEM and ODM custom services to increase branding for our global customers by providing them with the products they need.