Plastic packaging bags have become a preferred tool for storing and transporting food due to their convenience and versatility. Plastic packaging bags, especially those designed specifically for food, can effectively isolate air, moisture, and microorganisms, thereby extending the shelf life of food and maintaining its freshness.

Bu makalede, Huiyang Ambalaj will share the characteristics of plastic packaging bag types and their sealing guidelines and applications.

Classification of plastic packaging bags

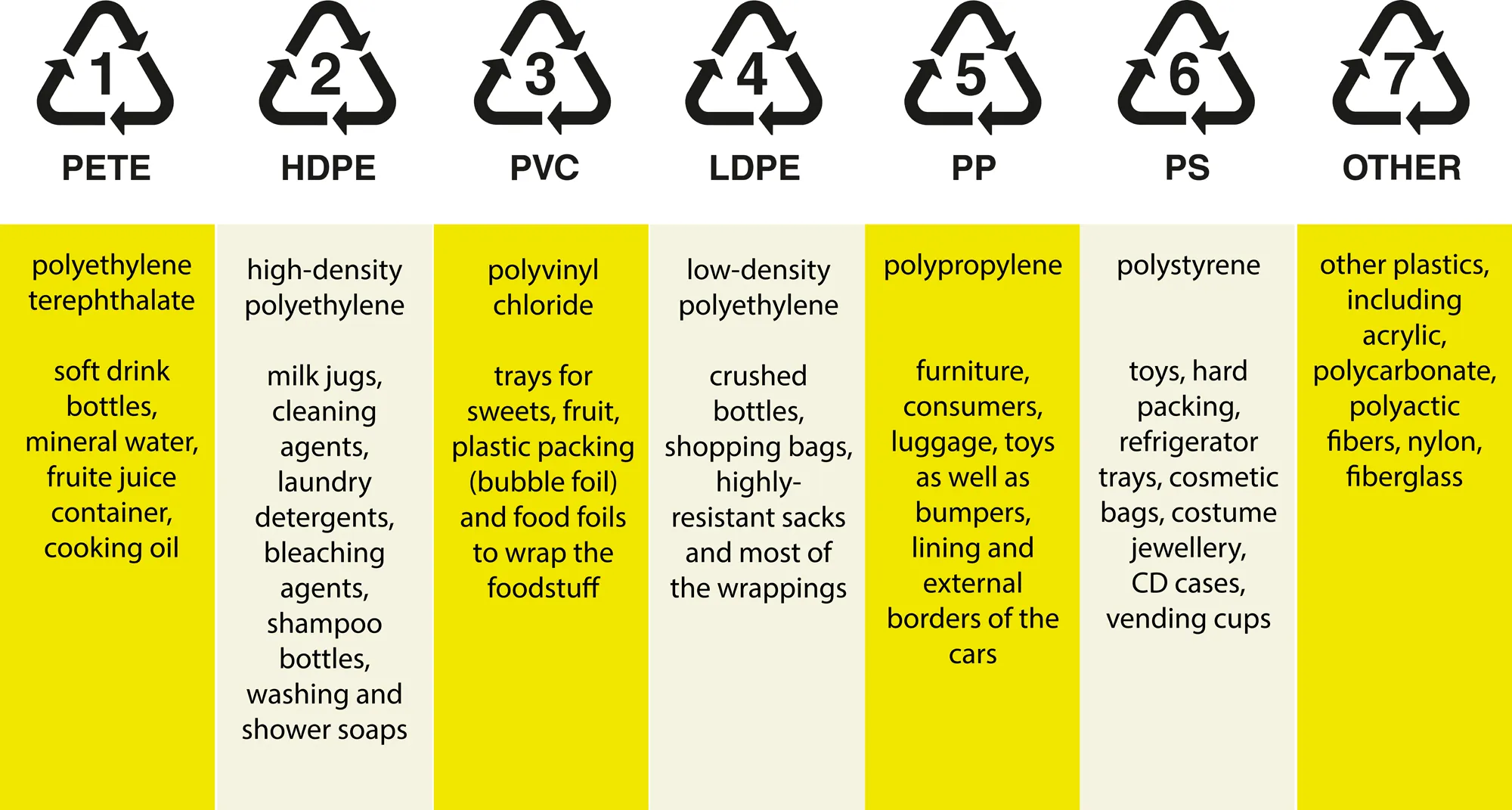

Plastic packaging bags can be divided into the following types according to material classification:

– OPP (biaxially oriented polypropylene)

– CPP (cast polypropylene)

– PP (polypropylene)

– PE (polyethylene)

– PVA (polyvinyl alcohol)

– EVA (ethylene-vinyl acetate copolymer)

– Composite bags (composite of multiple layers of materials, such as PET/PE, BOPP/PE, etc.)

– Co-extruded bags (multi-layer bags formed by co-extrusion of multiple plastics)

Polyethylene (PE) and polypropylene (PP) are trendy materials in the food packaging industry, mainly due to their safety, heat resistance, and transparency. Here is a detailed explanation of these two materials and the application of polyethylene terephthalate (PET) in food packaging:

Polyethylene (PE)

Polyethylene is a common thermoplastic that is divided into several types, including low-density polyethylene (LDPE), linear low-density polyethylene (LLDPE), and high-density polyethylene (HDPE). PE materials have the following characteristics:

- Safety: PE is non-toxic and approved by the U.S. Food and Drug Administration (FDA) for food contact applications.

- Heat resistance: Although PE is not as heat resistant as PP, some types of PE, such as HDPE, can withstand higher temperatures.

- Transparency: PE has good transparency, making food packaging easy to observe.

- Moisture resistance: PE has good moisture resistance and is suitable for food packaging that requires moisture protection.

Polypropylene (PP)

Polypropylene is a lightweight, strong plastic that offers the following benefits:

- Safety: PP is also considered safe and approved for food packaging.

- Heat resistance: PP has better heat resistance than PE, can withstand higher temperatures, and is suitable for sterilizing microwave ovens and hot water.

- Transparency: PP can be manufactured to be transparent or translucent, and is also available in opaque versions.

- Chemical resistance: PP has good resistance to most chemicals.

Polyethylene terephthalate(PET)

Polyethylene is a common thermoplastic that is divided into several types, including low-density polyethylene (LDPE), linear low-density polyethylene (LLDPE), and high-density polyethylene (HDPE). PE materials have the following characteristics:

- Barrier properties: PET can effectively block the penetration of oxygen, moisture, and flavors, which is very important for maintaining the freshness of food and extending its shelf life.

- Transparency: PET has extremely high transparency, which makes it ideal for beverage bottles and display packaging.

- Recyclability: PET is recyclable, which helps reduce environmental pollution.

In general, PE and PP are widely used in food packaging due to their safety, transparency, and heat resistance, while PET is particularly suitable for the packaging of food and beverages that need to be stored for a long time due to its excellent barrier properties.

Sealing technology and principle

Heat sealing technology: This is the most commonly used sealing method in the industry. The plastic film is heated to melt it, and then cooled and solidified under pressure to form a seal. Heat sealing can ensure the tightness of the packaging bag and prevent the penetration of air and moisture.

Cold seal technology: Suitable for heat-sensitive foods, such as some dairy products and candies. Cold seal uses special adhesives to bond the edges of the package at room temperature, which is easy to operate and low in cost.

Ziplock bags: These plastic bags are equipped with a self-locking closure that can be opened or closed by the user with a simple sliding motion. They are suitable for home storage and convenient for repeated use.

Vacuum Sealing: The air in the bag is extracted using a vacuum pump and then sealed. This technology can greatly reduce the oxygen content and prevent food oxidation. It is particularly suitable for long-term storage of meat, cheese, and dry goods.

Application in practice

Dry food storage: Use polyethylene bags to pack dry food such as grains, nuts, biscuits, etc., seal them by heat sealing or self-sealing, and place them in a dry and ventilated place to effectively prevent pests and mildew.

Fresh food: For vegetables, fruits, and meat, it is recommended to use plastic bags with good air permeability, such as perforated PE bags, which can maintain a certain amount of air circulation, reduce moisture accumulation, and avoid rotting.

Frozen food: PET and polyethylene composite bags are ideal for frozen food due to their good low-temperature resistance. After sealing, they can be placed in the freezer of the refrigerator to preserve food for a long time without affecting its quality.

Condiments and spices: Use aluminum-plastic composite bags or PET bags, these materials have good oxygen and water vapor barrier properties, which can maintain the freshness and aroma of spices and condiments.

Tips

- Before using plastic packaging bags, make sure your hands and food surfaces are clean and dry to avoid the introduction of bacteria and moisture.

- Try to squeeze out the air in the bag. For foods that cannot be vacuum sealed, you can use a straw to help evacuate the air.

- Choose the most suitable packaging bag material and sealing method based on the characteristics and storage requirements of the food.

- Check the stored food regularly. If you find signs of deterioration, you should deal with it immediately to avoid affecting other foods.

Plastic packaging bags are an indispensable tool for modern food storage. Through reasonable use and advanced sealing technology, they can significantly extend the shelf life of food, reduce food waste, and also provide a strong guarantee for food safety. With the continuous advancement of technology, plastic packaging bags will be more environmentally friendly and efficient in the future, bringing more convenience to our daily lives.

In Summary

The fact is that properly sealing plastic packaging bags is essential for effective long-term food storage. Whether you choose to heat-seal or vacuum-seal, ensuring a tight seal helps to maintain the quality, freshness, and extended shelf life of your food. With Huiyang Ambalaj outlined in this complete guide, you can store your food in plastic packaging bags with confidence. We are socially responsible for food safety and an eco-friendly environment. We provide one-stop flexible packaging service solutions. We always use food-grade and environmentally friendly raw materials. Each process has a quality inspection mechanism combining machine and manual labor. Quality is always our pursuit, while our production capacity is constantly improving. We guarantee that every batch of products will satisfy our customers, please feel free to contact us.