Do you often need to clean out your fridge of expired food? If this annoys you, why not try using a retort pouch?

Retort pouches are composite plastic film pouches that can be heat-treated and can be used to package food in a flexible packaging format, usually by sterilization at high temperatures and pressures, allowing aseptic packaging of a wide range of food products, ranging from water to fully cooked, heat stabilized meals (e.g. ready-to-eat meals that can be eaten cold, heated by immersion in hot water, or heated by the use of a heater), with lighter weight and lower transport costs. Steamer pouches are often used as an alternative to cans or glass jars, as they offer the same benefits as these packaging options, with some additional advantages.

The U.S. Army promoted the concept of retort pouch packaging in 1950, and research continued until 1960. The retort pouch was invented by the U.S. Army Natick Soldier Research, Development and Engineering Centre, Reynolds Metals and Continental Flexible Packaging, who were jointly awarded the Food Technology Industry Achievement Award for the invention in 1978. The thin packaging design of the high-temperature retort pouch reduces cooking time by up to 60 per cent, improves food quality and facilitates rapid reheating. Advantages include ease of portability, reheating, space savings, and easy disposal after use. It is widely adopted by the US military and is known as “Meals Ready to Eat” (MRE).

In the 1950s, the US Munitions Food and Container Institute conducted extensive research. Swedish, Italian and Japanese companies have also carried out research and production of retort pouches. In 1968, Japan’s Otsuka Foods introduced Bon Curry bags. Today, retort pouches are made of PET film, aluminium foil and polypropylene film laminated together. A transparent retort pouch can be produced with SiOx-coated PET instead of an aluminium foil layer for heating in microwave ovens.

In short, high-temperature retort pouches are an efficient, safe and convenient form of food packaging, widely used for ready-to-eat meals, soups, sauces and pet food. In this article, Huiyang Packaging will comprehensively explain the features, advantages and sustainability of retort pouch and other guidelines.

Retort Pouch Packaging Advantages: Why Choose Retort Pouches

1)High temperature resistance: High retort pouches can withstand high temperature and high pressure sterilization treatment, usually under 121°C conditions to withstand 30 minutes, large packaging can last 60 minutes. Keep the product sterile. The tightness of these packages also prevents items from coming into contact with oxygen, thus extending shelf life. All common microorganisms are killed during this heating process to prevent them from spoiling.

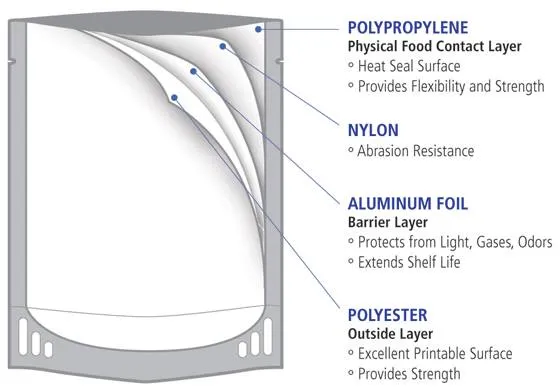

2)Multi-layer structure using materials: High temperature retort pouches are composed of multiple layers of materials, each layer has a specific function. Commonly used materials include plastics (such as PET, polypropylene) and aluminum foil. These materials work together to ensure the bag’s high temperature resistance and versatility. Durable materials reduce the possibility of contamination of internal products due to external wear. These flexible bags consist of 4 layers and include the following:

- Polyester outer layer (high-temperature resistance, toughness and printability) Nylon second layer (wear resistance) for increased strength and printability;

- Aluminum foil (blocks light, gas, microbes, odors. Extend the shelf life, hardness allows tearing gap) to provide moisture, light, and anti-Qigong;

- Polypropylene in food contact layer (hot cover, flexibility, strength, food resistance) for heat sealing and food contact

3)Lightweight and flexible design: Retort pouches are lighter and easier to carry and store than traditional metal and glass jars. In addition, the flexibility of the bag allows it to adapt to the needs of different shapes and sizes of food packaging. You can print directly on the entire surface of the retort pouches, providing more choice and freedom for product packaging design. There are many customization options for retort pouches, such as the shape, the materials used and whether they include features such as spouts or European-style punch handles.

4)Extended shelf life: High temperature retort pouches can extend the shelf life of food without refrigeration, ensuring that food can be stored for a long time at room temperature.

5)Maintain food quality and nutrition: Since the retort pouch is able to heat food quickly and evenly, the cooking time is reduced, and the nutrients and flavor of the food are better retained. Heating efficiency helps items retain their color, smell, taste and nutritional value compared to longer exposure during sterilization.

6)Space-saving and easy storage: They are made of flexible materials and are easier to store in warehouses, supermarkets and other retail locations. The materials used are light in weight, which reduces the cost of transporting goods between different locations. Products don’t need to be refrigerated or frozen, which makes it easier for retailers to store and display them, while also reducing food waste.

7)Consumer convenience: Compared to opening glass or metal cans, consumers can easily open the retort pouch by tearing or LIDS. Retort pouch packaging has advantages over other methods because it is cheaper than glass or glass jars, lighter than metal jars, and does not require refrigeration after opening the package. In addition, the steamer packs are suitable for everyday use, as they can be opened with just one hand – perfect for busy moms!

8)Environmental impact and recyclability: Retort pouches are easier to handle and recycle than traditional packaging, and they are safer to handle and dispose of than products packaged in metal or glass jars. Less impact on the environment.

Application of High Temperature Retort Pouches

Depending on their everyday use, retort pouches are widely used in the food and beverage industry as they are a durable, lightweight and cost-effective alternative to metal and glass jars in packaging for the food processing industry. The food and beverage sector is followed by the healthcare sector.

- Ready-to-eat meals: Retort pouches are widely used in the packaging of ready-to-eat meals, which is convenient for consumers to quickly heat and eat.

- Soups and sauces: Retort pouches are suitable for packaging soups and sauces to ensure that they retain their original taste and flavor after high-temperature treatment.

- Pet food: Retort pouches are also widely used in pet food packaging, which can extend the shelf life, but also easy to carry and store.

- Special foods: High-temperature Retort pouches are also used to package some special foods, such as medical nutrition and military rations, to ensure their safety and stability in special environments.

In general, the high temperature retort pouch is a very practical packaging supplies, not only to help us relaxed cooking, but also to maintain the nutrition and freshness of the ingredients. If you haven’t tried the high temperature boiling bag yet, try it!

Retort Pouch Manufacturing and Processing

High temperature retort pouch production process

The production process of the digester bag includes extrusion, lamination and heat sealing of multiple layers of material. Each layer of material is carefully treated to ensure its stability and functionality under high temperature conditions.

The first printing step involves printing mylar bags made of laminate. Fill the bag with raw materials, before the retort pouch is sealed, the air in the filling bag is removed to remove most of the air and then sealed by pulse. After the bags are sealed, it is transferred to a reverse rack or tray, each bag is housed in a separate compartment or tank, and finally these bags are autoclaved.

Sterilization and sealing methods

After the retort pouch is filled with food, it is sterilized by high temperature and high pressure to ensure the sterile state of the food in the bag. The sealing process uses heat sealing technology to ensure the firm and sealing of the bag mouth. Prepare the food first (raw or cooked) and then seal it into a retort pouch. The bag is then heated under high pressure in a digester or autoclave to 240-250 °F (116-121 °C) for a few minutes. The food inside is cooked in a manner similar to pressure cooking. This process reliably kills all common microorganisms (especially Clostridium botulinum), preventing them from spoiling. The packaging process is very similar to canning, except that the packaging itself is flexible. The laminated structure does not allow gas to penetrate into the bag from the outside. The structure of retort pouches varies from application to application, as liquid products require different barrier properties than dry products, similarly, acidic products require different chemical resistance than alkaline products.

The Future Trend of High Temperature Retort Pouch Packaging

High temperature retort pouches not only perform well in terms of food quality and convenience, but also play an important role in sustainable development. The sustainability of packaging should be a major consideration, as the benefits of choosing more environmentally friendly packaging go beyond reducing the carbon footprint. Consumers consciously make purchasing decisions based on the sustainability of products, from product development to packaging.

By reducing resource consumption, reducing waste, extending food shelf life, eliminating refrigeration, improving transportation efficiency, using renewable materials and environmentally friendly design, retort pouch packaging makes a positive contribution to environmental protection and resource conservation. In the future, with the continuous progress of technology, the material and production process of the retort pouch will be continuously improved to further enhance its performance and function. In the market growth and trends, the retort pouch market will continue to grow, especially in the field of ready-to-eat food and pet food, its application prospects are broad. In terms of innovation in materials and design, the material of the retort pouch will be more environmentally friendly, and the design will be more diversified to meet the needs of different consumers and market changes.

Cooperate with Retort Pouch Packaging Supplier

Huiyang Packaging specializes in all types of bag packaging, no matter what bag style you are looking for, such as foil/aluminum foil self-standing digester bags, clear digester bags, foil flat digester bags with mouth digester bags, or bag materials – materials used in each layer of the bag. Choose finishes such as aluminum, kraft paper or transparent, or add other features to your retort pouch such as spouts, corner braces, punch handles, valves, etc., as well as sizes and custom brands, we have customized services.

We can also provide you with advice and expertise when exploring different packaging options for your products. We aim to make the process as simple as possible, providing transparency and advice on the various decisions you need to make. Sustainability is at the heart of everything we do and we are always exploring new initiatives and ways to improve our sustainability so that we pass this value on to you and your customers. If you need someone to guide you through the process, or if you are confident and have a vision, we welcome the opportunity to discuss your packaging needs.